AS9100 Series PDCA Structure Explained

Unpacking the AS9100 Series PDCA Structure: The Continuous Cycle Driving Aerospace Quality

Introduction

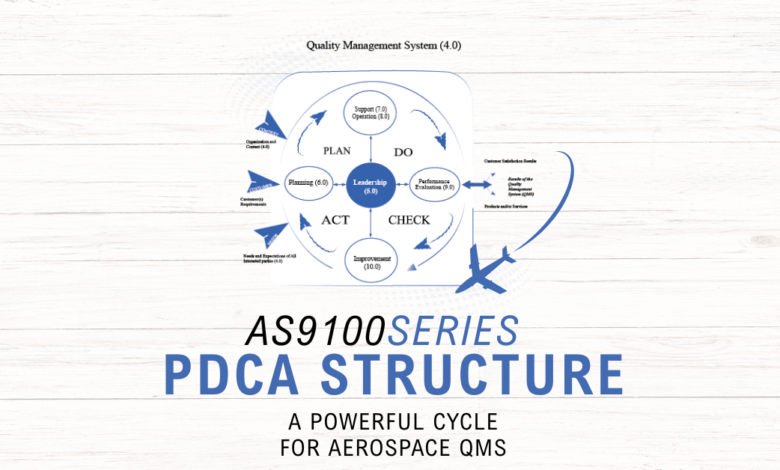

The AS9100 series of standards, which includes AS9100D, AS9110, and AS9120, is the aerospace industry’s foundation for quality management. Built upon ISO 9001, the AS9100 series strengthens requirements to address the high stakes of aviation, space, and defense manufacturing. At the heart of these standards lies the Plan Do Check Act (PDCA) structure, a dynamic cycle that ensures organizations continually improve while balancing safety, reliability, and compliance.

Why PDCA Is Central to the AS9100 Series

The PDCA cycle, originally developed by Walter Shewhart and later popularized by W. Edwards Deming, is more than a quality management concept. In the AS9100 series, PDCA is the organizing framework that ties together every requirement, from leadership commitment to process control and improvement.

For aerospace organizations, where one oversight can have critical consequences, PDCA ensures that processes are planned with intention, executed with discipline, monitored for effectiveness, and refined for continuous improvement.

Mapping AS9100 Clauses to PDCA

Plan

Clauses 4, 5, and 6 form the planning stage of the quality management system.

- Clause 4 – Context of the Organization: Define internal and external issues, understand the needs of interested parties, and establish the scope of the QMS.

- Clause 5 – Leadership: Ensure top management demonstrates commitment, sets policy, and aligns quality objectives with business strategy.

- Clause 6 – Planning: Identify and address risks and opportunities, set measurable objectives, and plan changes to the system.

Do

Clauses 7 and 8 bring the planning to life through support and operational execution.

- Clause 7 – Support: Manage resources, infrastructure, environment for operations, competence, awareness, communication, and control of documented information.

- Clause 8 – Operation: Plan, implement, and control processes for product and service provision, including design and development, external provider (supplier) management, production, and delivery.

Check

Clause 9 evaluates whether the system is effective and aligned with objectives.

- Monitoring and Measurement: Collect data to assess process and product performance.

- Internal Audit: Conduct audits at planned intervals to verify conformity and effectiveness.

- Management Review: Evaluate system performance, review risks, and ensure alignment with organizational goals.

Act

Clause 10 ensures the system continually improves and adapts.

- Nonconformity and Corrective Action: Address failures, perform root cause analysis, and prevent recurrence.

- Continual Improvement: Use data, audits, and lessons learned to strengthen the system over time.

- Adaptation: Adjust the QMS to reflect changing risks, customer needs, and business strategy.

Beyond the Basics: PDCA as a Living System

Risk-Based Thinking Throughout

AS9100D requires risk to be considered in every stage of the quality management system. From planning and operations to review and improvement, risk awareness is inseparable from PDCA.

A Spiral, Not a Line

PDCA is a repeating cycle that spirals forward. Each pass builds on the last, raising the maturity of the quality system over time. This makes the organization more resilient and adaptable.

Micro and Macro Cycles

PDCA works on multiple levels. At the macro level, it drives the entire quality system. At the micro level, individual processes such as supplier evaluation or employee training also follow PDCA cycles, creating layers of improvement.

How PDCA Strengthens Aerospace Compliance

Embedding PDCA into an aerospace quality management system delivers clear benefits, including:

- Leadership alignment and accountability

- Operational discipline and resource control

- Data-driven decision making from performance reviews

- Continuous improvement through corrective and preventive action

Conclusion

The AS9100 series PDCA structure is not a checklist but a mindset that strengthens every part of aerospace quality management. By mapping each clause of the standard to PDCA and applying it as a living cycle, organizations ensure compliance, improve efficiency, and raise performance.

Ronnie Lee Roberts II has worked in the Department of Defense (DoD) quality space since 2017, supporting programs at Patuxent River and Webster Field (NAWCAD/NAVAIR). He has worked as a certified AS9100:2016 Rev D Lead Auditor (2022-2025), ISO/IEC 20000-1:2018 Lead Auditor (TPECS [2023]), and a Certified CMMI® Associate (2025) with experience supporting CMMI-DEV Level 3 environments. His expertise spans technical writing, document control, CAD design, logistics management, and quality control. Ronnie specializes in inspecting to specification, ensuring contract compliance, and preparing teams for success in high-stakes, audit-ready environments.

AssessmentDrive® Early Access List

Sign up to be among the first to receive access to the AssessmentDrive® family of compliance products including Clause 8.1.4 Counterfeit Parts prevention (AS9100D/IA9100).

Source link